Automatic Engraving Machines: Types, Prices, and Tips

Automatic engraving machines are like the overachievers of the crafting and manufacturing world; they work fast, never tire, and produce stunning results.

Whether engraving metal nameplates, customizing wooden gifts, or marking parts in a factory, an automatic engraving machine does the job with precision and style. But with so many options like CNC, CO₂, diode, fiber, and UV, it can feel like a tech buffet.

Don’t worry; we will break it down so you can choose the perfect automatic engraver that fits your needs (and budget).

How Do Automatic Engraving Machines Work

An automatic engraving machine is a type of Computer Numerical Control (CNC) device that uses a computer and specialized software to precisely control a tool and create permanent designs, text, or images on a material's surface.

The machine translates a digital design into a set of commands (like G-code) that dictate the tool's movement, speed, and power, ensuring high precision and repeatability.

There are two primary types of automatic engraving machines, which differ fundamentally in how they interact with the material:

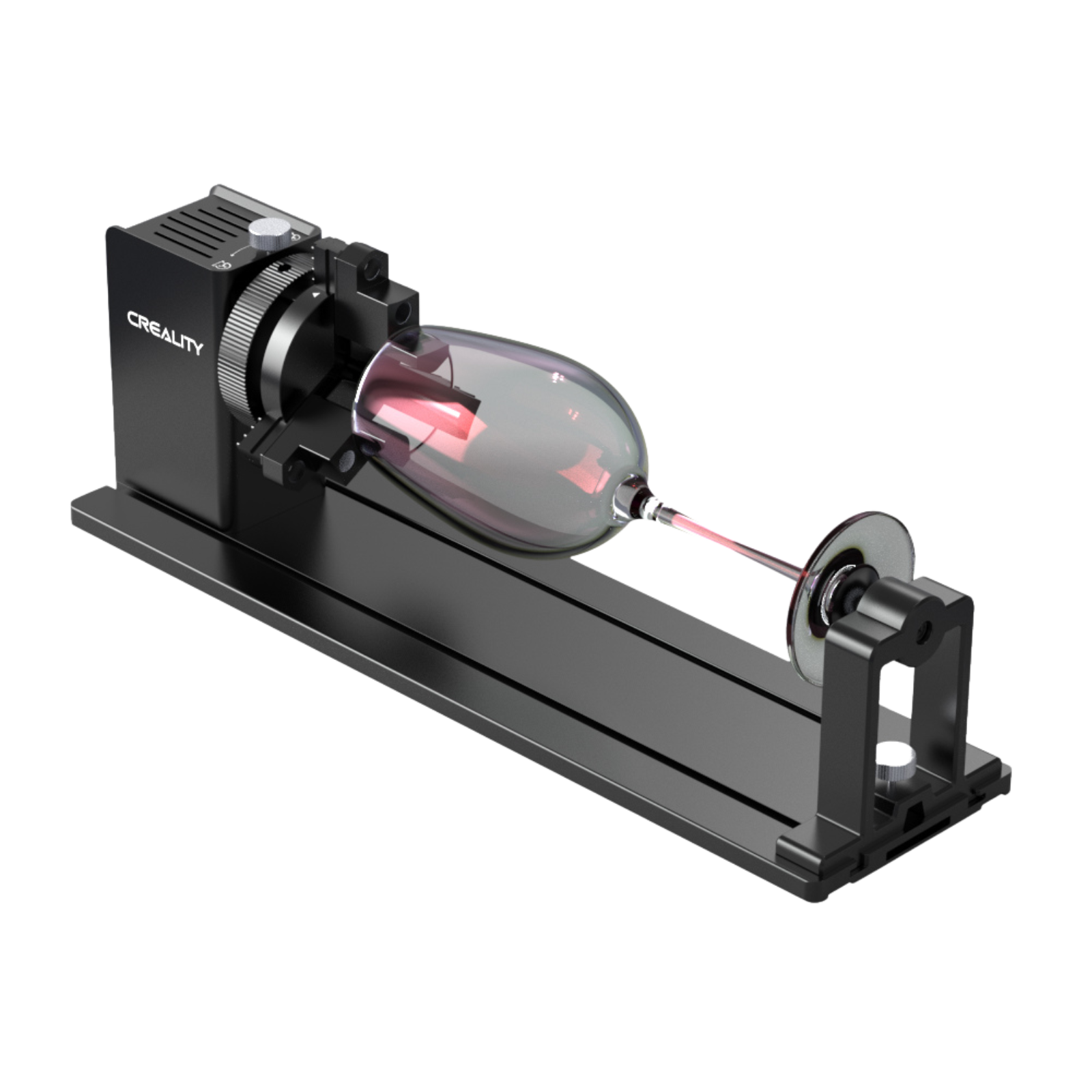

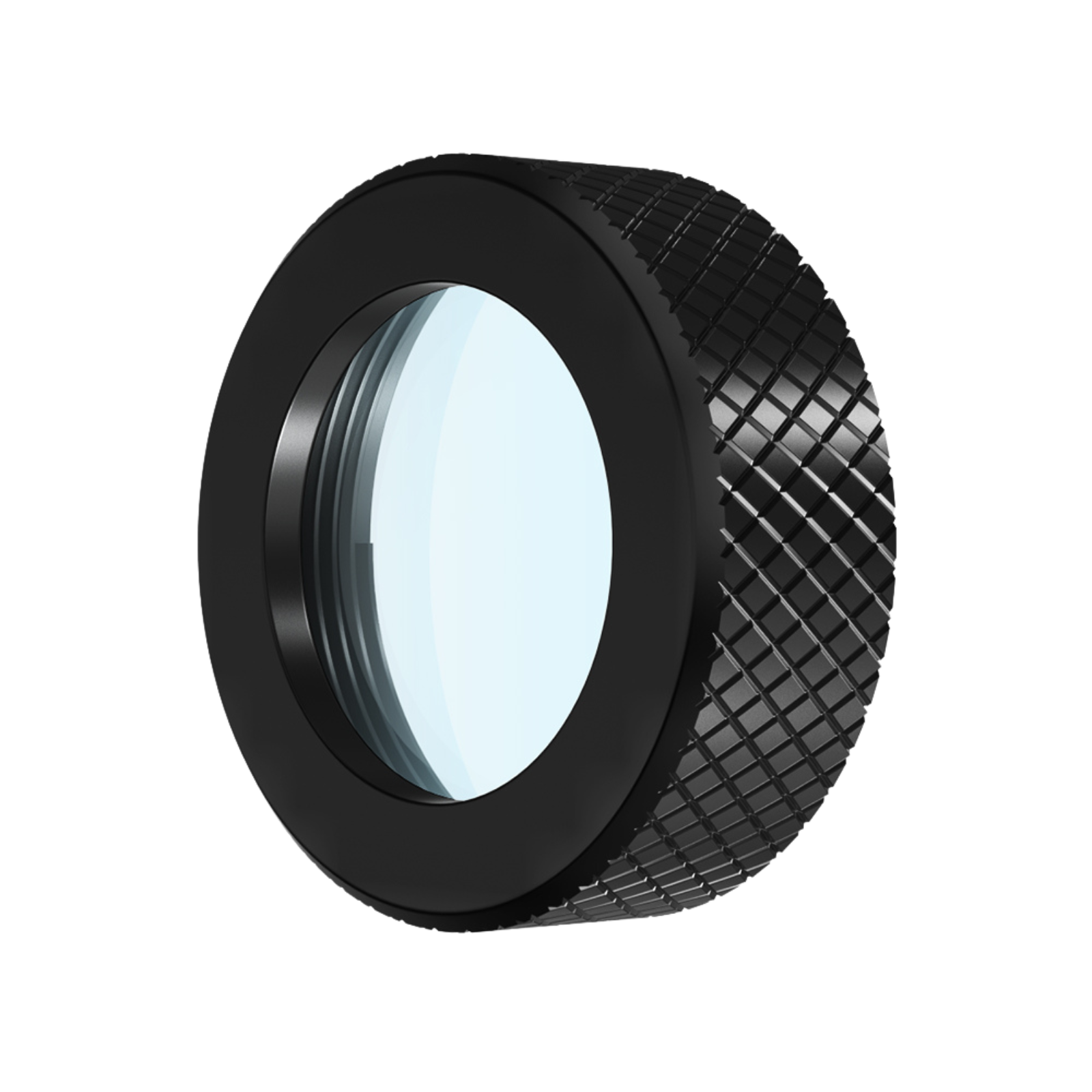

- CNC Laser Engraver: Laser engravers are non-contact machines that use a focused beam of light to mark or remove material.

- CNC Rotary Engravers Work: Rotary engravers are contact machines that use a physical, rotating cutting tool to physically carve into a material.

4 Types of Automatic Engraving Machines You Should Know (2025)

Different projects demand different automatic laser marking machines, and each type shines in its own way.

Here’s a quick guide to the four main types—what they do best, where they excel, and what you should remember before investing in one.

1. CO₂ Laser Engravers

CO₂ laser engravers are the go-to machines for many creatives and small businesses. They use a high-powered CO₂ laser beam to vaporize or burn the material's surface, leaving behind precise engravings.

These machines are especially good with non-metal materials like wood, acrylic, leather, glass, and fabric, making them perfect for personalized gifts, signage, and craft products.

The results are smooth, detailed, and professional-looking. While these automatic engraver machines can engrave coated metals, they aren’t ideal for bare metals without additional treatments. They’re a great mix of speed and quality.

Pros:

- Excellent for wood, acrylic, leather, and glass projects

- High precision and clean edges

Cons:

- Struggles with engraving bare metals without coating

- Glass tubes in some models need replacement over time

2. Diode Laser Engravers

Diode laser engravers are compact, portable, and budget-friendly for beginners or hobbyists. They use a laser diode (similar to the tech in barcode scanners but much stronger) to burn or mark the surface.

These machines are lightweight, easy to set up, and great for home projects like customizing wooden boards, engraving leather wallets, or marking anodized aluminum.

They work well for small-scale production but don’t match the raw power of CO₂ or fiber lasers. Still, for many crafters, they offer the right balance between cost, portability, and ease of use.

Pros:

- Affordable and beginner-friendly

- Compact and easy to move or store

Cons:

- Limited power for cutting thick materials

- Slower on dense or hard surfaces

3. Fiber Laser Engravers

Fiber laser engravers are the industrial powerhouses of the engraving world. They use fiber optic cables to deliver an incredibly focused laser beam, perfect for engraving metals, plastics, and certain ceramics.

These machines are blazing fast, maintenance-free, and can produce permanent marks for serial numbers, logos, and intricate patterns.

Industries like automotive, electronics, and jewelry rely heavily on fiber lasers for high-volume production. While they come with a higher price tag, the speed, precision, and low upkeep make them a worthwhile investment for serious businesses.

Pros:

- Extremely fast and accurate for metal marking

- Low maintenance and long lifespan

Cons:

- Higher upfront cost

- Not ideal for engraving non-metal materials

4. UV Laser Engravers

UV laser engravers are the specialists for ultra-fine, delicate marking. They use short-wavelength ultraviolet light, which interacts with materials without generating much heat through a process called “cold marking.” This makes them perfect for heat-sensitive materials like plastics, glass, silicon wafers, and medical tools.

They can produce tiny, detailed markings without damaging the surrounding surface. Industries like electronics and healthcare love UV lasers for their ability to engrave microtext or codes. However, they’re not designed for deep cuts or large-scale carving, so they’re best suited for precision tasks rather than heavy-duty jobs.

Pros:

- Ideal for heat-sensitive and delicate materials

- Extremely fine and detailed marking capabilities

Cons:

- Expensive compared to other laser types

- Not suitable for deep engraving or cutting

Top-Rated Automatic Engravers Users Love

With so many automated laser cutters and engravers on the market, it can be tricky to pick the right one. To make life easier, we’ve rounded up some of the most loved automatic engraving machines that deliver on performance, versatility, and value

1. xTool F2 Ultra 60W MOPA

The xTool F2 Ultra 60W MOPA is a powerhouse for hobbyists and professionals who want the flexibility to work with different materials, metals, plastics, leather, and more.

It can adjust laser pulses for different textures and colors, making it ideal for creative and industrial projects.

It’s fast, precise, and portable enough to move around your workspace. The dual-laser setup lets you handle various engraving tasks without switching machines, saving time and space.

Whether you’re making jewelry, custom tools, or signage, this machine delivers crisp results every time.

Price: $6,499.00

Pros:

- Handles a wide range of materials with precision

- Dual-laser design for versatile engraving styles

Cons:

- Higher price point than beginner machines

- Slight learning curve for complete newcomers

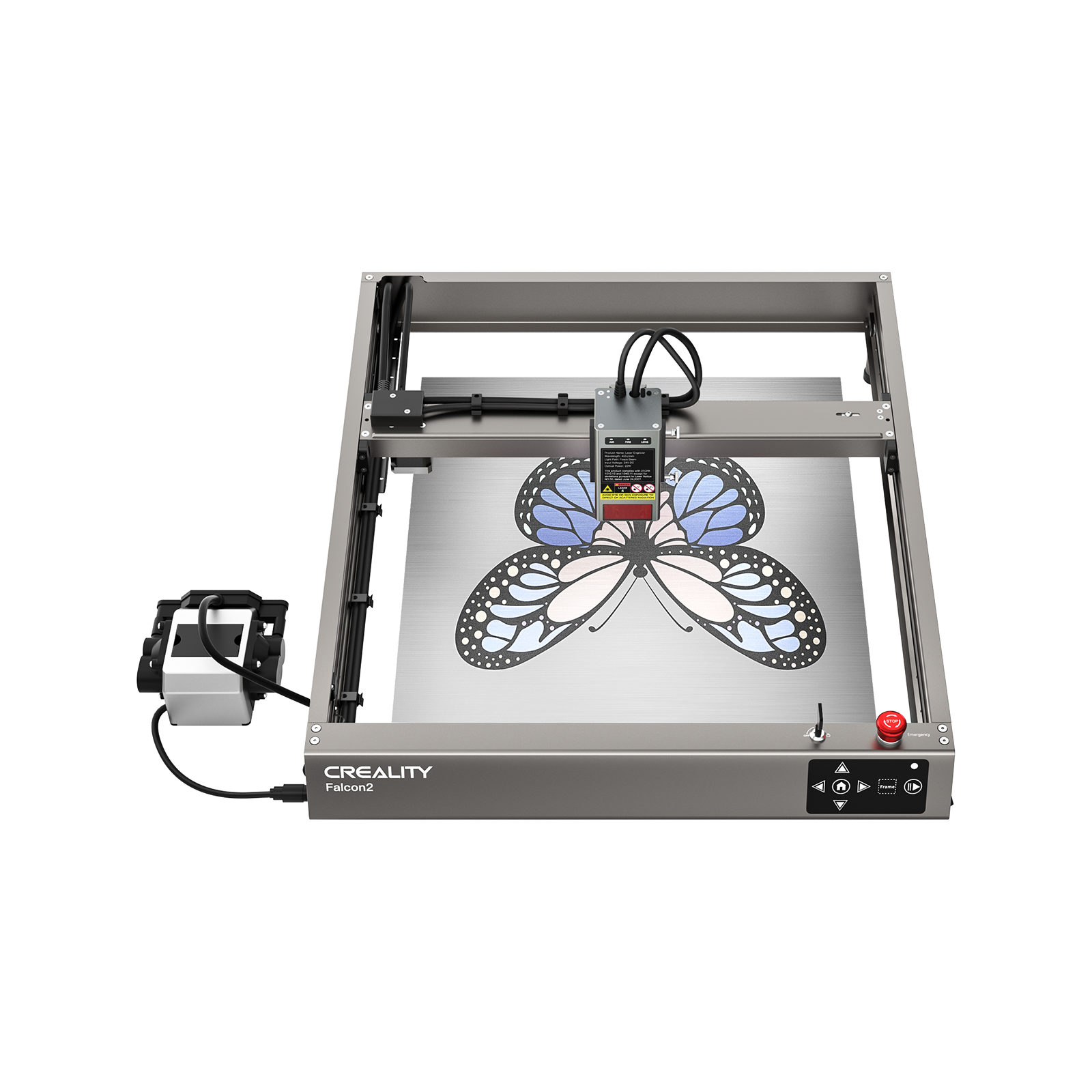

2. Falcon2 Pro

The Falcon2 Pro is a sleek, high-speed automatic laser marking machine and engraver that blends professional-grade power with user-friendly controls.

It’s known for its impressive cutting speed, which is perfect for small businesses or busy workshops that want to handle multiple projects quickly.

It works on wood, acrylic, stainless steel, leather, and more, meaning you won’t have to limit your creativity.

With enhanced safety features, air assist, and precision focusing, it’s designed for long-term use without burning out. Plus, it has a compact footprint, so it won’t hog your workbench.

Price: $2,949.00

Pros:

- Super-fast engraving and cutting speeds

- Works with a wide variety of materials

- Built-in air assist for cleaner cuts

- Compact and stylish design

- Easy-to-use interface for beginners and pros

Con:

- Slightly louder than some other engravers

How Much Does an Automatic Engraver Cost

The cost of an automatic engraver can vary dramatically, ranging from a few hundred dollars to hundreds of thousands, depending on the type of technology, power, size, and intended use (hobbyist vs. industrial).

Here is a breakdown of the typical price ranges for the most common types of automatic engraving machines:

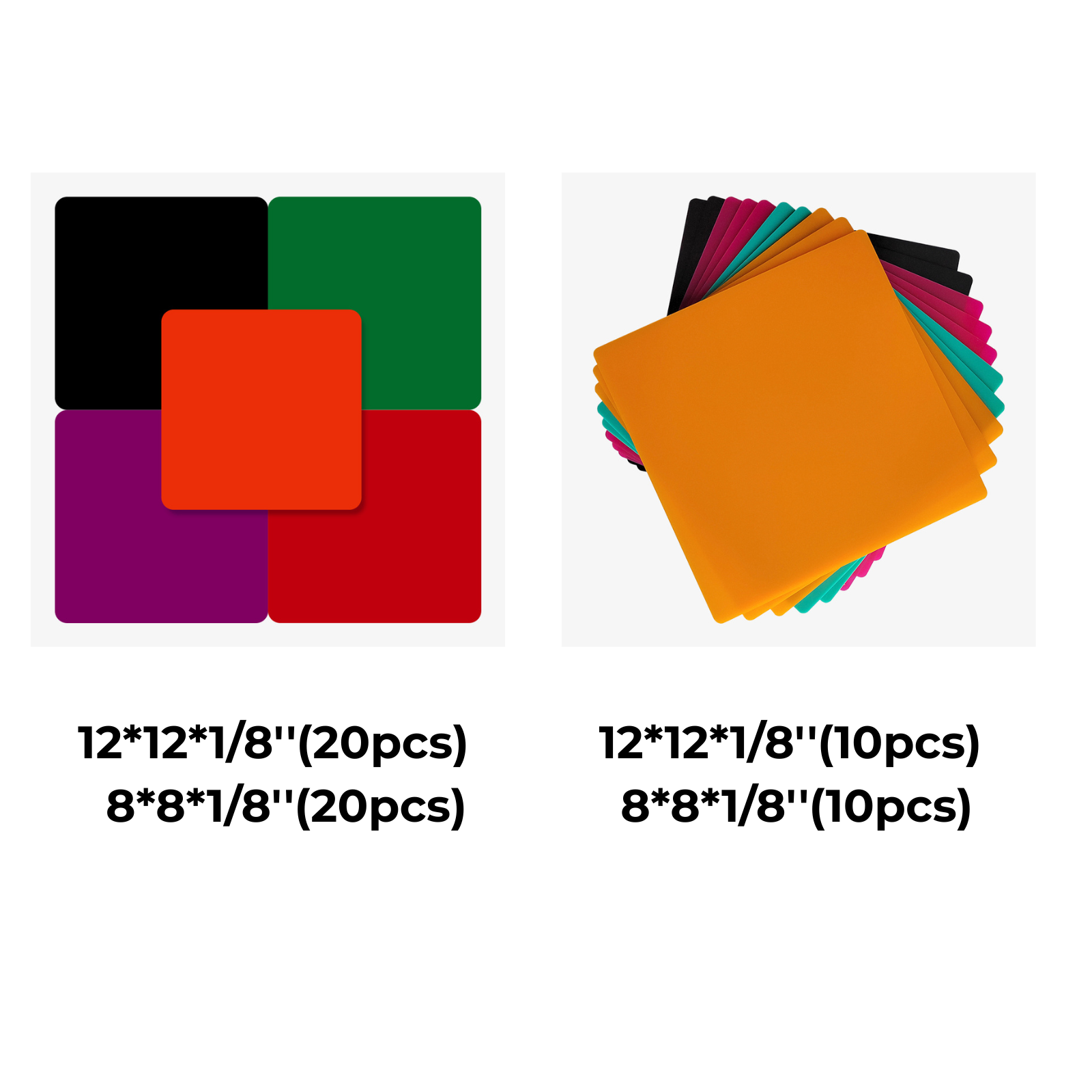

1. Diode Laser Engravers:

- Hobbyist/Entry-Level: $200 - $1,000.

- Enclosed/Professional: $1,500 - $3,000.

2. CO2 Laser Engravers

- Desktop/Compact: $1,500 - $6,000.

- Mid-Range (Hobby & Small Business): $3,000 - $15,000.

3. Fiber Laser Engravers

- Desktop/Small-Scale: $2,500 - $8,000.

- Industrial/High-Power: $8,000 - $30,000+.

4. UV Laser Engravers

- Entry-Level/Desktop: $3,000 - $10,000.

Automatic or Manual Engraving: Which Is Better for You

Choosing between automatic and manual engraving is a classic decision that depends entirely on your goals, budget, skill level, and the nature of your projects. Both methods have distinct advantages and disadvantages, and the "better" option is the one that aligns with your specific needs.

|

Feature |

Automatic Engraving |

Manual Engraving |

|

Primary Use |

High-volume, repeatable production, high-precision details |

One-of-a-kind art, custom work, deep cuts |

|

Best For |

Business, manufacturing, creating products, quick results |

Artisans, unique gifts, high-end jewelry, sculptural work |

|

Speed |

Very fast |

Very slow |

|

Precision |

Extremely high (machine-perfect) |

Varies (human-made) |

|

Cost |

High initial investment in machine, low cost per piece |

Low initial tool cost, high cost per piece (labor) |

|

Skill Level |

Beginner to intermediate (with software) |

Expert (years of practice) |

|

Key Advantage |

Speed, accuracy, consistency, efficiency |

Artistic authenticity, depth, flexibility |

In Conclusion

Automatic engraving machines have revolutionized how we personalize and mark materials, whether you’re a hobbyist making custom gifts or a business producing in bulk. With options ranging from affordable diode lasers to powerful fiber engravers, there’s something for every budget and need.