Buyer's Guide: Laser Engraving Machine for Plastic

Engraving plastic can transform everyday items into custom, practical creations, from personalized name tags and durable labels to unique gifts. A laser engraver for plastic unlocks endless possibilities for small businesses, DIY crafters, and anyone needing permanent identification for parts and tools.

However, not all plastics are created equal. Some engrave cleanly, while others may warp or release harmful fumes. This can make the process seem confusing before you even begin.

This guide will walk you through everything you need to know: which plastics are best for engraving, the right type of laser to use, essential safety tips, and our top picks for the best plastic label engraving machines in 2025.

The Best (and Worst) Plastics for Laser Engraving

Not all plastics are suitable for a laser engraver. Some materials give you sharp, clean results, while others can melt, warp, or even release toxic fumes. Knowing the difference will save you time, money, and frustration.

Plastics That Work Great

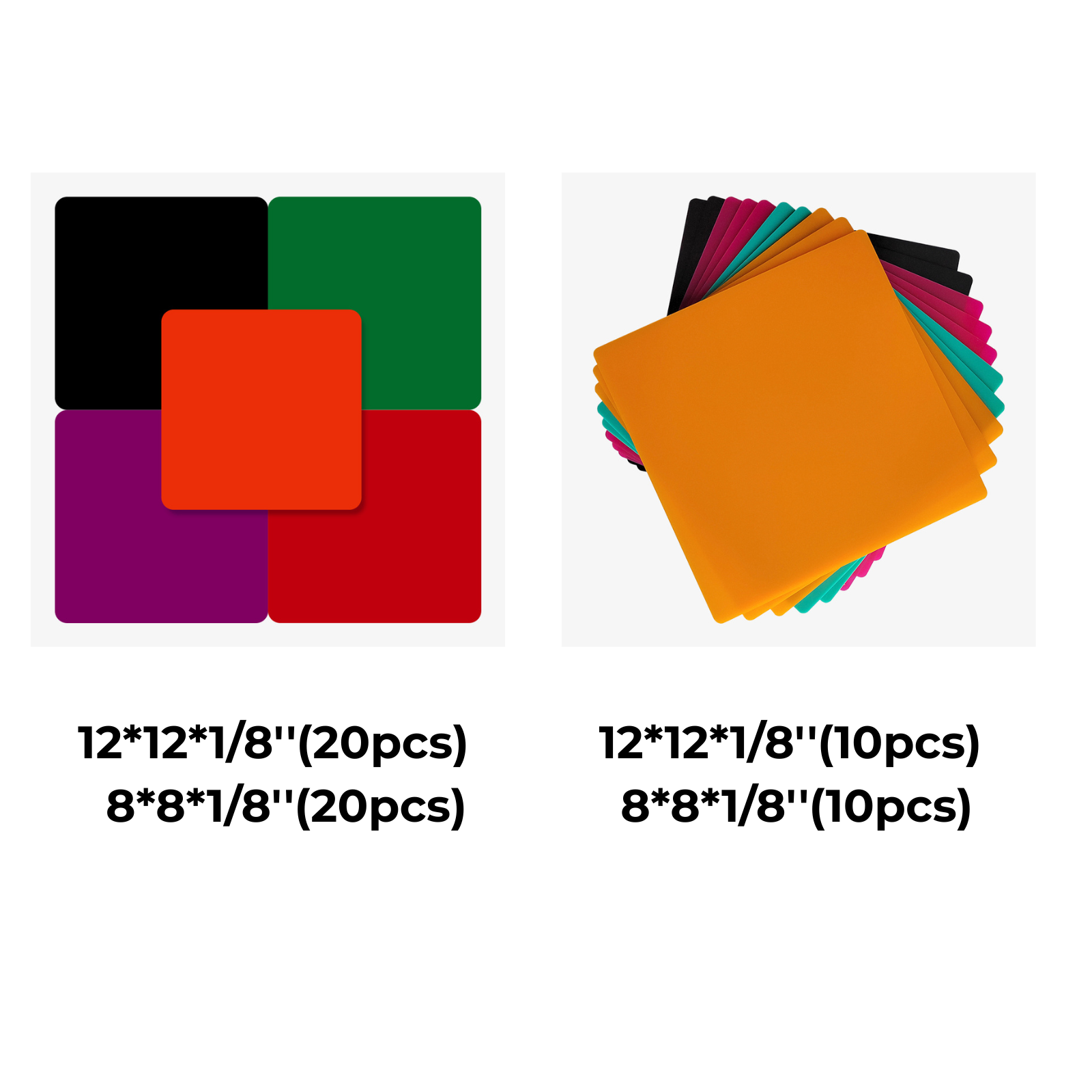

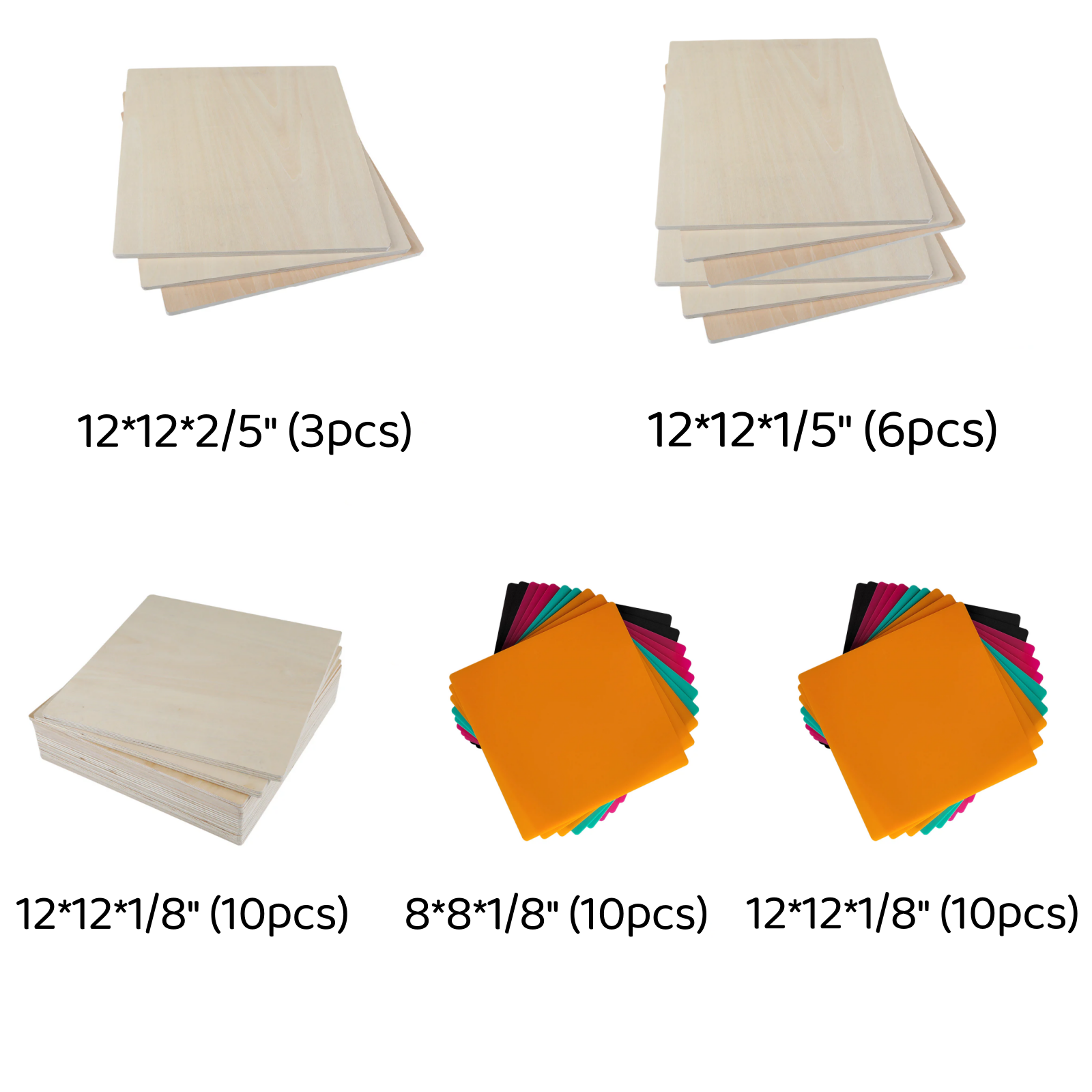

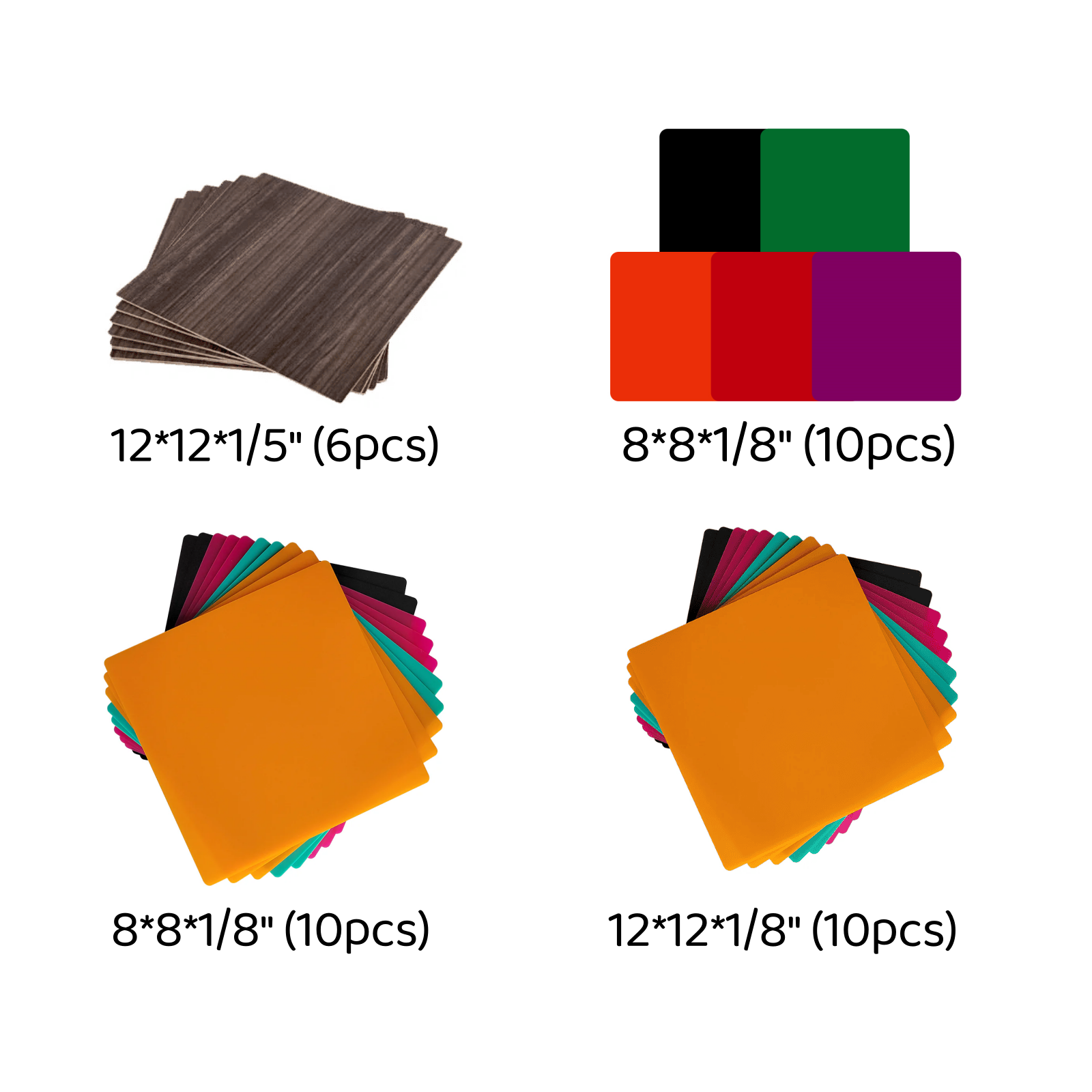

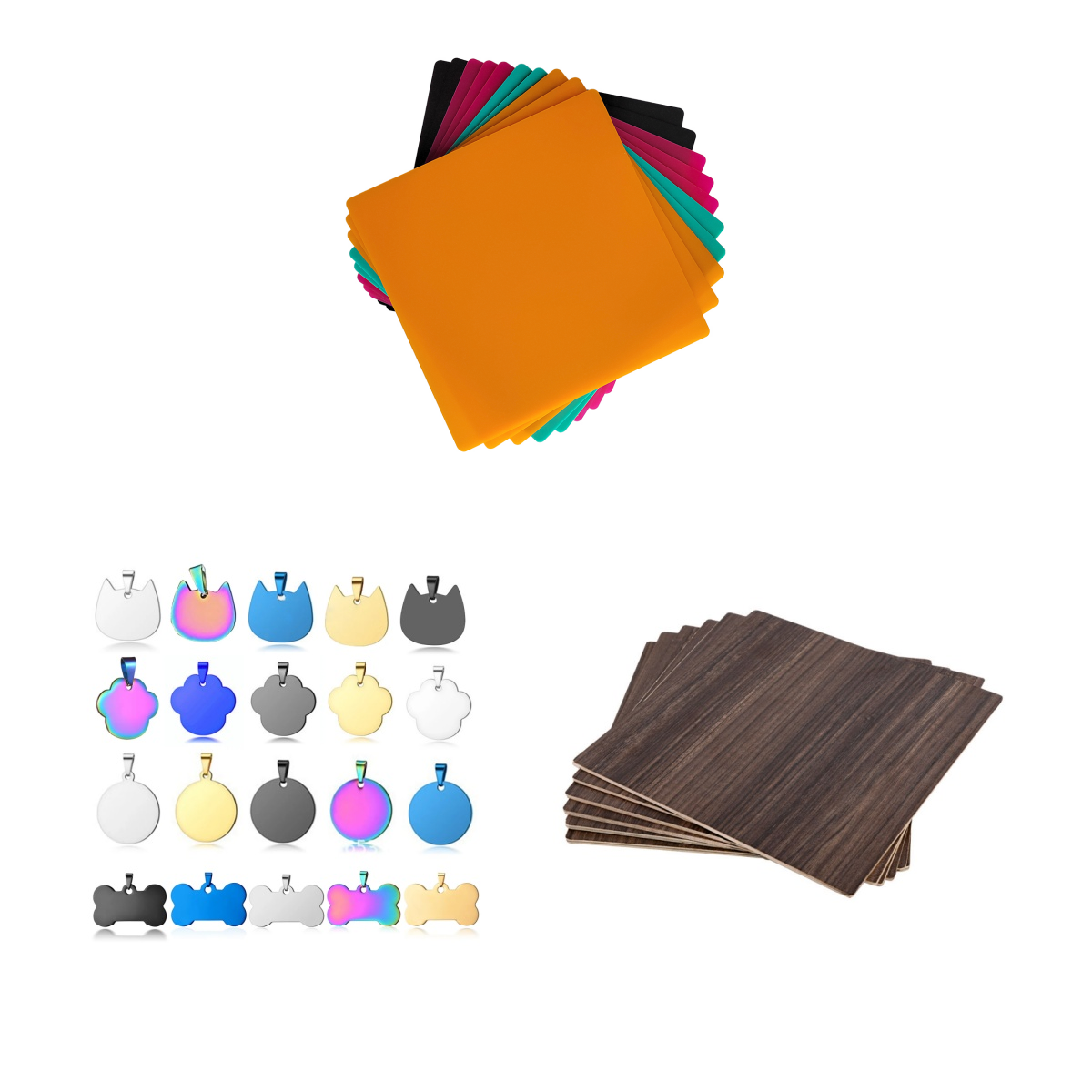

1. Acrylic (PMMA)

Why it works: Acrylic is a laser engraver's best friend because it absorbs the laser's energy cleanly and predictably. This allows for smooth, precise cuts and produces a beautiful, frosted white mark that offers high contrast against the clear material.

- Common Items: It's widely used for creating signs, display cases, custom awards, trophies, and personalized keychains.

2. ABS Plastic

Why it works: ABS is a durable, impact-resistant plastic that engraves well, leaving a clean, high-contrast mark. However, it requires careful power and speed settings to prevent melting.

- Common Items: ABS is found in many everyday objects like electronic housings, industrial tags, car dashboards, and LEGO® bricks. Proper ventilation is essential when engraving ABS, as it can release harmful fumes.

Plastics to Avoid

1. PVC (Polyvinyl Chloride)

Why it's bad: This is the most important plastic to avoid. When a laser engraves PVC, it releases chlorine gas, which is highly toxic to inhale and extremely corrosive. This gas will permanently damage your machine's optics, rails, and other metal components.

- Common Items: PVC is used to make pipes, vinyl siding, credit cards, and some types of clothing and flooring.

2. Polypropylene (PP)

Why it's bad: Polypropylene has a very low melting point. The heat from a laser will cause it to melt and deform rather than engrave cleanly, often resulting in a messy, unreadable mark and a sticky residue that can gunk up your machine.

- Common Items: You'll find PP in food containers, bottle caps, plastic chairs, and some types of reusable water bottles.

3. Polystyrene (PS)

Why it's bad: This material is highly sensitive to heat and is flammable. It melts and warps quickly, leading to poor results and posing a significant fire hazard. It can also produce a charred, fuzzy-looking mark.

- Common Items: PS is commonly used for disposable cutlery, foam packaging (like Styrofoam), and many model kits.

Based on a comprehensive analysis of plastics for laser engraving, acrylic (PMMA) is widely considered the best material for a majority of applications.

While other plastics like ABS are also good for certain applications (e.g., durable industrial tags), acrylic's superior finish, ease of use, and overall reliability make it the top choice for both hobbyists and professionals looking for the best results.

Which Laser is Most Suitable for Engraving Plastic

Choosing the right laser for plastic depends on the material, desired finish, and budget. Here is a breakdown of the most common laser types and their suitability for engraving plastic.

1. CO₂ Lasers: The Versatile Standard

With a wavelength of 10.6 µm, CO₂ lasers are the top choice for most plastic engraving applications.

They are highly effective on common materials like acrylic, ABS, and PETG. They excel at cutting cleanly and creating the distinctive frosted finish on cast acrylic, making them ideal for signs, awards, and custom labels.

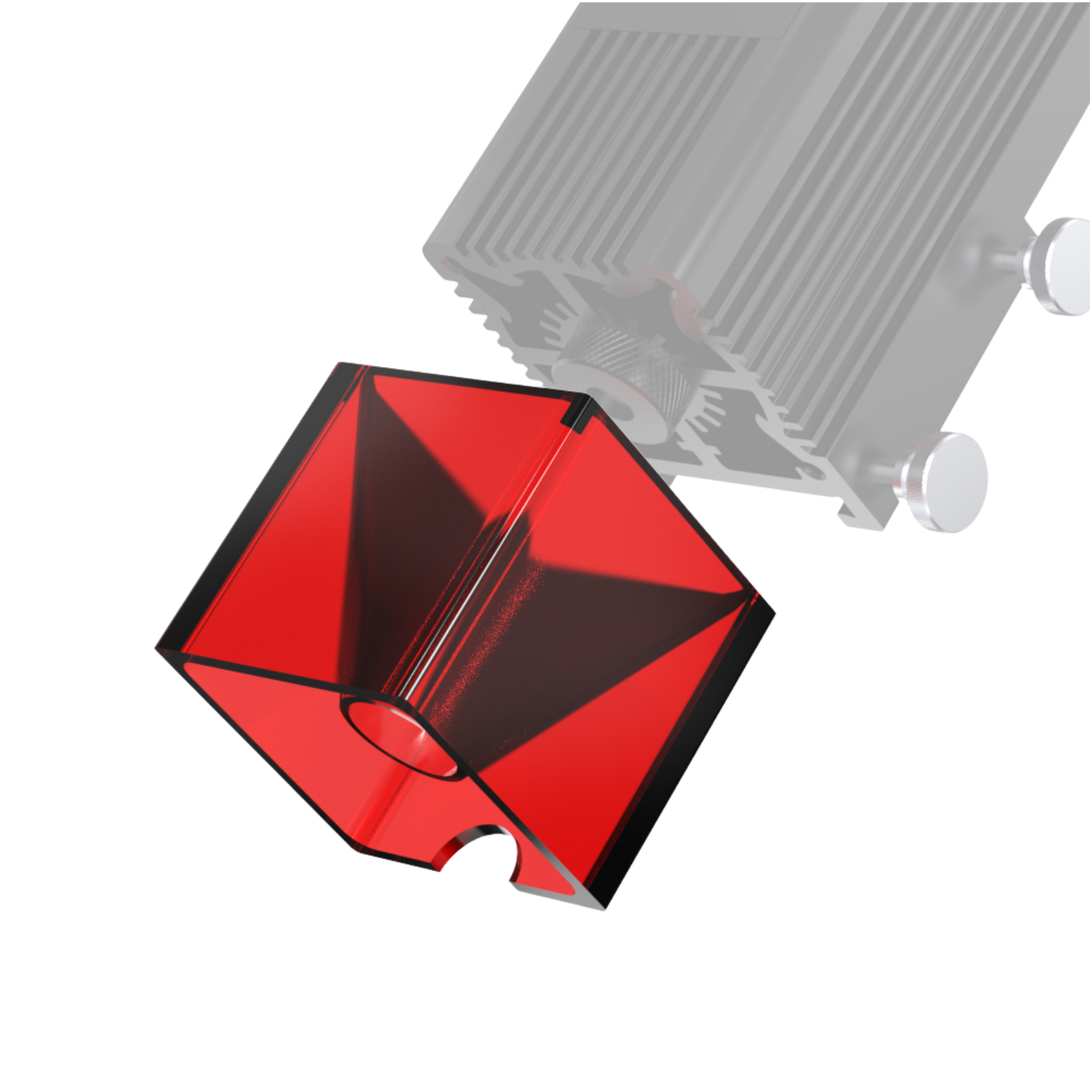

2. Diode Lasers: The Affordable Entry Point

Diode lasers are a popular, compact, and budget-friendly option.

While they are not as powerful as CO₂ machines, they are effective for surface marking and light engraving on certain pigmented or coated plastics. Due to their higher heat output, it's essential to use a faster speed and lower power to prevent melting and achieve a clean result.

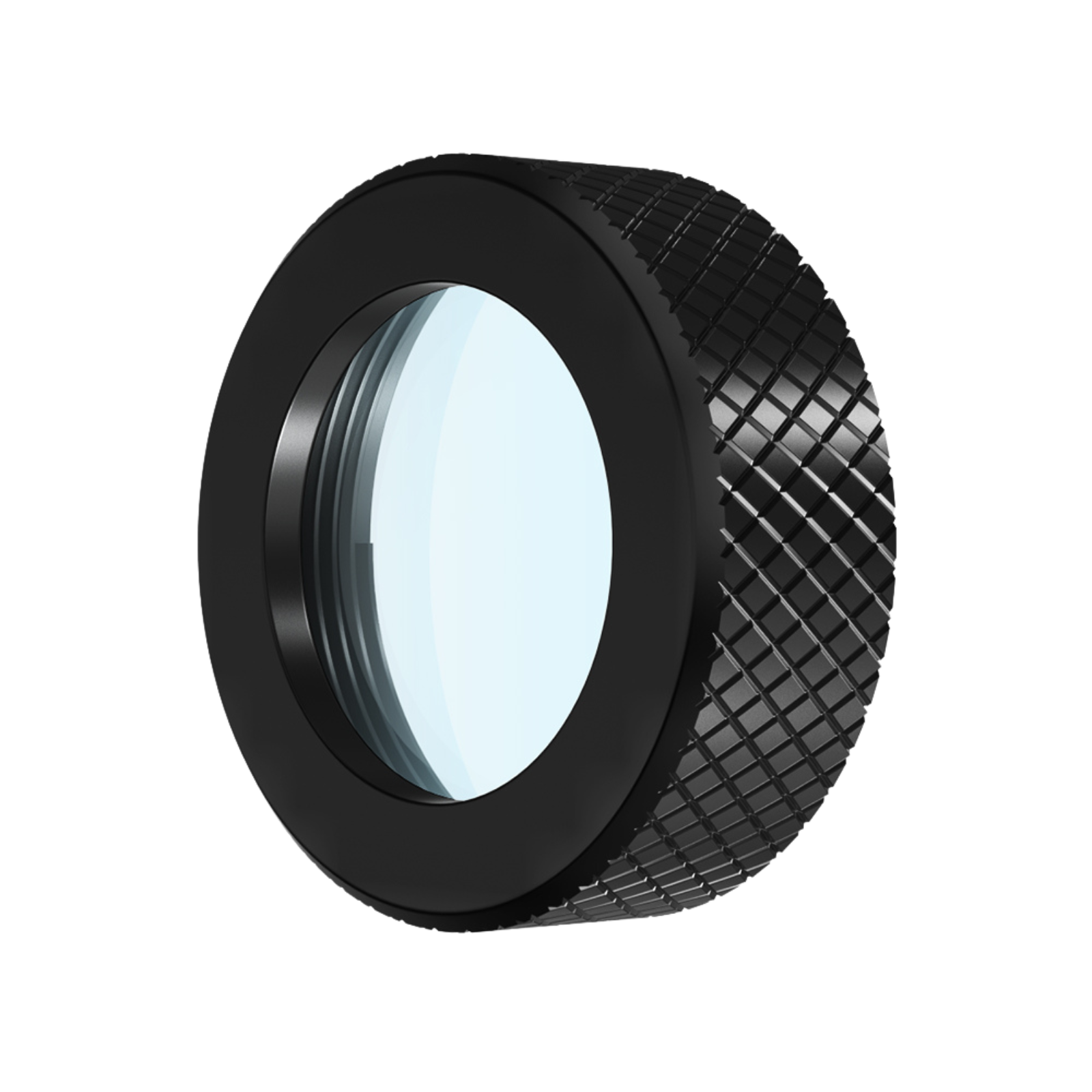

3. UV Lasers: The Precision Tool

UV lasers (355 nm wavelength) use a "cold marking" process that is perfect for heat-sensitive plastics.

They produce extremely fine, high-contrast marks without causing thermal damage, discoloration, or warping. This makes them the ideal, albeit more expensive, choice for high-detail work on medical devices, electronics, or other delicate parts.

4. Fiber Lasers: The Specialist for Metals (and some Plastics)

Fiber lasers (1064 nm wavelength) are primarily designed for marking and engraving metals.

While they are generally not the best choice for plastics, they can mark certain pigmented or engineered plastics by creating a contrast. However, they are often considered overkill for common plastics and can cause significant overheating.

For beginners and hobbyists, a CO₂ laser is the most versatile and reliable option for general plastic engraving. Diode lasers are a great starting point for non-transparent plastic.

Essential Safety Guidelines for Working with Plastics

Engraving plastic with a laser is an enjoyable and fulfilling activity, but safety should always come first. Plastics behave differently under a laser than wood or metal; some can release harmful fumes if not handled correctly.

Here are some simple, must-follow safety guidelines for working with plastics:

1. Know your plastic

Not all plastics are safe to engrave. Avoid PVC and vinyl completely as they release toxic chlorine gas. Stick to safe plastics like acrylic, ABS, PETG, and polycarbonate.

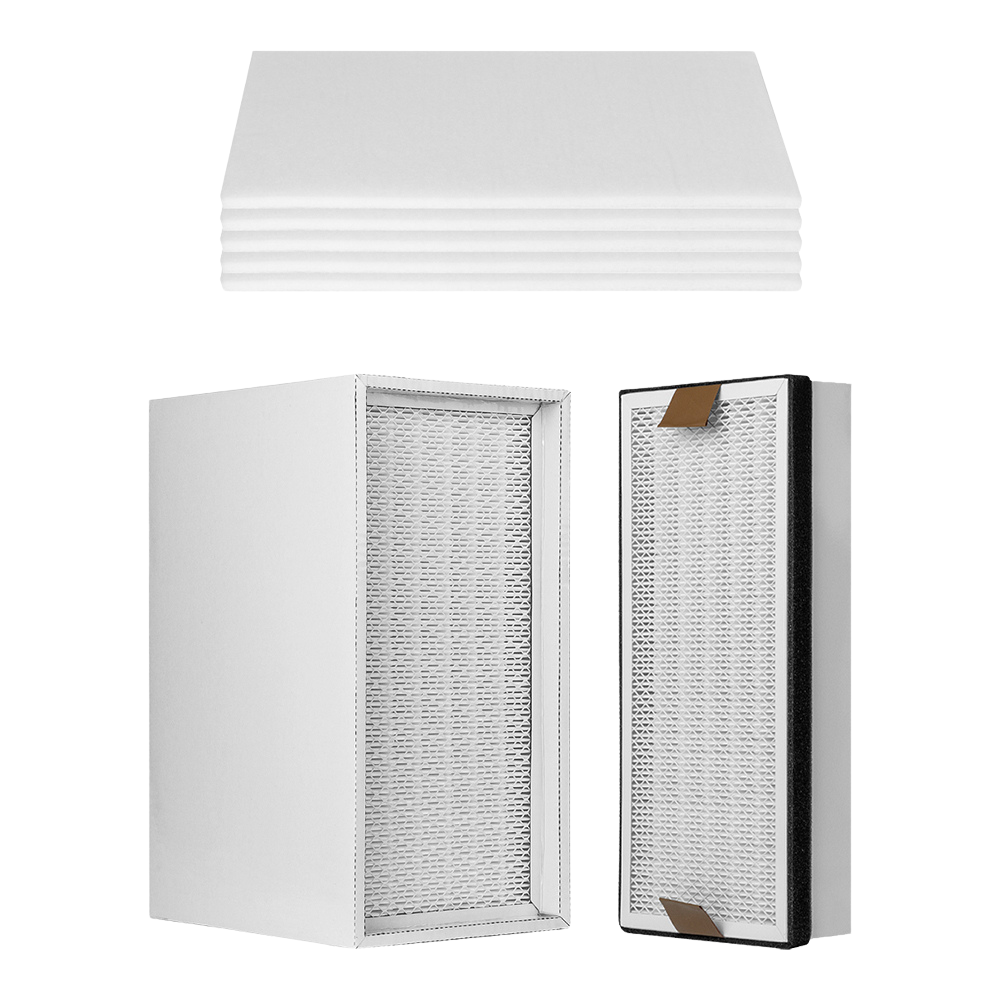

2. Work in a well-ventilated area

Plastics can give off fumes, so always use your laser engraver in a space with strong ventilation. If your machine has an exhaust fan or filtration system, ensure it’s running correctly.

3. Use proper protective gear

Wear safety glasses made for laser use and gloves when handling freshly engraved pieces, as edges can be sharp or hot.

4. Watch your settings

Plastics can melt or warp if you use too much power or too slow a speed. Always test on a scrap piece first and adjust your settings gradually.

5. Never leave the machine unattended

Plastics are flammable, and a moment of inattention can lead to trouble. Stay close by while your project is running.

6. Clean up properly

Dust and small melted pieces can accumulate. Keep your workspace and laser bed clean to prevent fire hazards and keep engravings sharp and precise.

Following these steps keeps you safe and ensures better engraving results. A little care goes a long way in making plastic engraving smooth, secure, and enjoyable.

The 4 Best Laser Engravers for Plastic

When it comes to engraving on plastic, not every plastic label engraving machine is created equal. Some are built for speed and precision, while others are better for budget-friendly DIY projects.

To help you choose the right fit, we’ve rounded up four of the best options of 2025. Each machine comes with its own strengths (and a few weaknesses), so let’s break them down one by one:

1. OMTech Polar [CO2 Laser]

The OMTech Polar is popular among hobbyists and small businesses who want a reliable CO2 laser for engraving plastic. With its 55W power, it can easily handle detailed engravings on acrylic, ABS, and coated plastics. It also comes with a built-in water chiller and air assist, making it a ready-to-use package right out of the box.

Price: Around $2,099

Pros:

- Great precision and engraving depth on plastics

- Comes as a complete package with air assist and chiller

Cons:

- On the heavier side, not very portable

- Higher price point compared to diode lasers

2. xTool P2 [CO2 Laser]

If you’re looking for a more advanced option, the xTool P2 is a strong contender. With its 55W CO2 laser and large working area (600mm x 308mm), it’s built for both professional engraving and small-scale production. It’s especially good for cutting thicker acrylic sheets while keeping the edges smooth.

Price: Around $3,999

Pros:

- Large working area, ideal for bigger projects

- Excellent at cutting and engraving acrylic with smooth results

Cons:

- Very expensive for beginners or hobby users

- Requires regular maintenance and calibration

3. AtomStack Hurricane [CO2 Laser]

AtomStack’s Hurricane series is designed for users who want power and speed without completely breaking the bank. Its 70W CO2 laser is stronger than most entry-level machines, and it can easily engrave or cut through thicker plastics. The machine also has a user-friendly interface that makes it easier for beginners to get started.

Price: Around $2,829

Pros:

- High power for faster engraving and cutting

- Easy-to-use interface for beginners

Cons:

- Bulkier than most desktop CO2 lasers

- Can be loud during operation

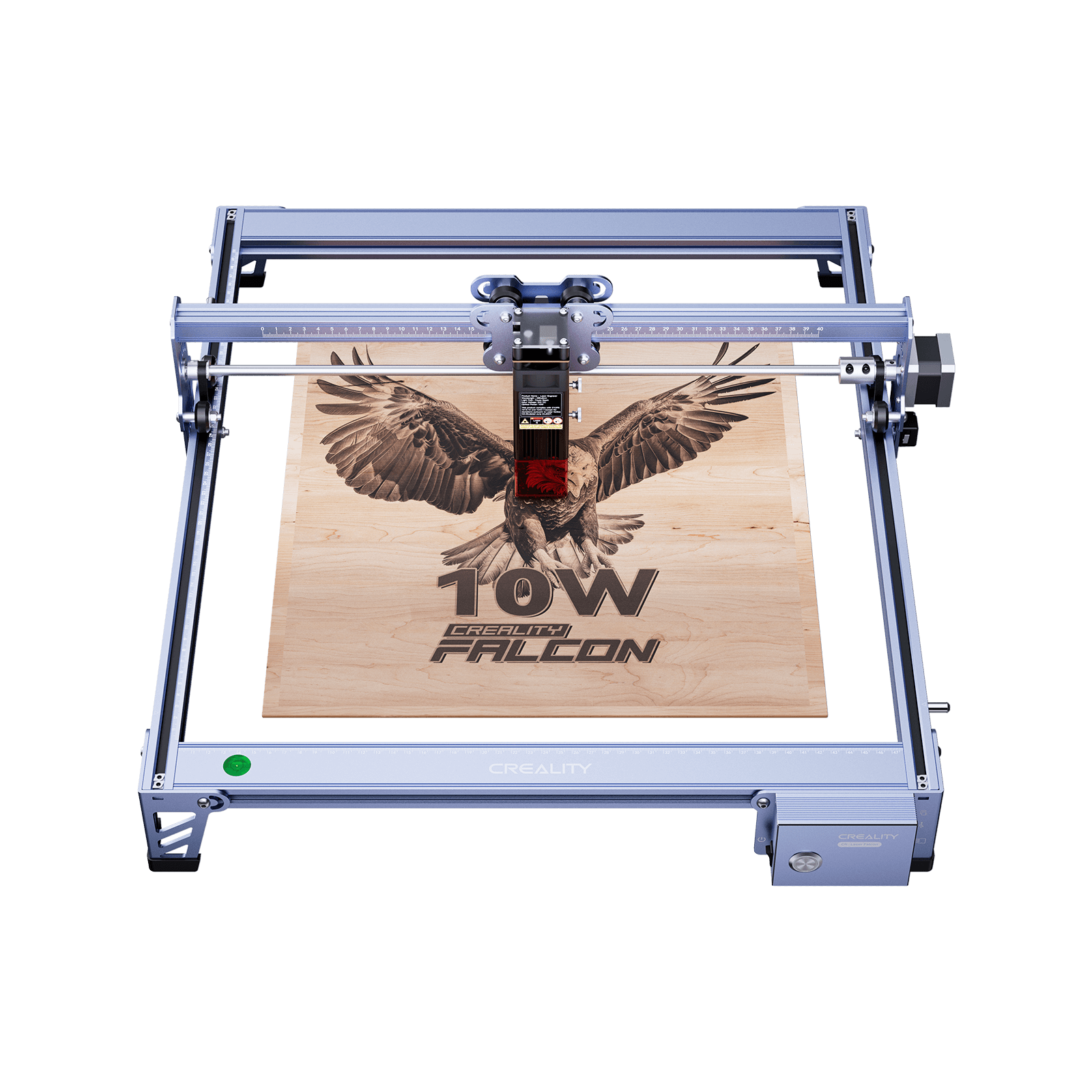

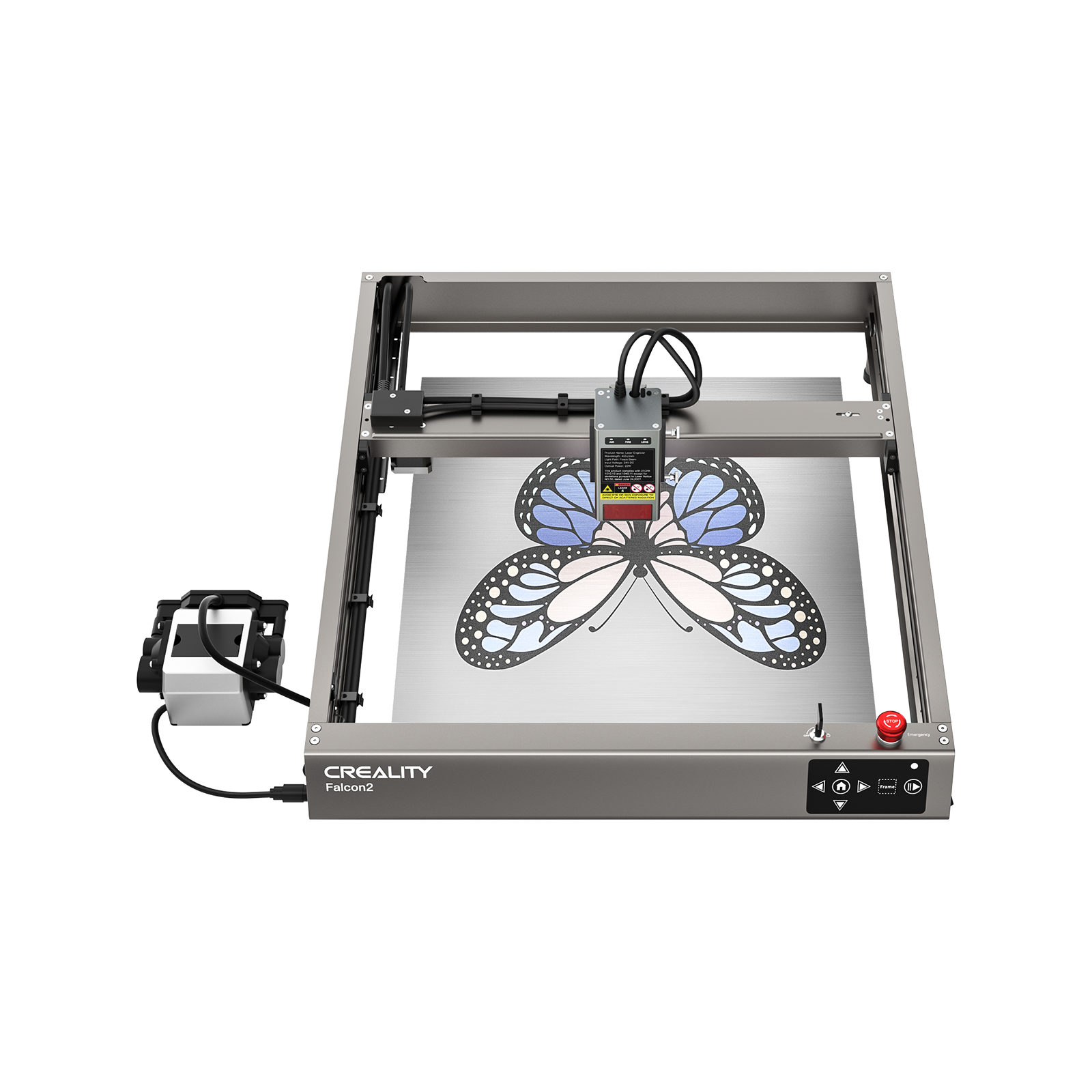

4. Falcon A1 Pro [Diode Laser]

The Falcon A1 Pro is the budget-friendly champion of the group, and for good reason. Unlike the CO2 machines, this laser engraving machine for plastic uses a high-power diode laser, making it more affordable while still capable of engraving on a wide variety of plastics, especially coated or treated ones. It’s compact, easy to set up, and perfect for beginners or small business owners who don’t want to spend thousands on a CO2 machine.

Price: Around $$1,099

Pros:

- Extremely affordable compared to CO2 lasers

- Compact and portable design

- Simple setup, beginner-friendly

- Works well with coated plastics and acrylics

- Low maintenance requirements

- Great entry point for hobbyists or small businesses

- Good balance of price and performance

Con:

- Users might need a little understanding to master advanced settings.

If you are just starting out or want an affordable, reliable machine for plastic engraving, the Falcon is hard to beat. It gives you a lot of value without overwhelming you with setup or maintenance costs, making it an excellent choice for everyday engraving needs.

Conclusion

Learning to engrave plastic is a rewarding hobby, perfect for labeling equipment, creating décor, or starting a micro-business. CO₂ lasers deliver clean results on acrylic, ABS, and coated sheets. Beginners in small spaces can start with a compact diode machine. Test on scrap, ensure ventilation, and your projects will shine.