Colour Laser Etching Tutorial: From Setup to Finish

Color laser etching sounds like magic — turning metal surfaces into rainbows of art. But it’s not as tricky as it seems.

This hands-on tutorial walks you through every step, from setup to the perfect colorful finish.

Part 1: How Color is Created During Laser Etching

Color during laser etching—especially on metals like stainless steel or titanium—is created through a process called laser-induced oxidation or thermal chemical reaction on the material’s surface. Here’s how it works, step-by-step:

1. Laser Heat Alters the Surface Oxide Layer

When a laser beam precisely heats the metal surface, it causes a controlled chemical reaction with oxygen in the air, forming a thin oxide layer.

The thickness of this layer determines what wavelengths of light are reflected vs. absorbed—similar to how oil on water creates rainbows.

This phenomenon is called thin-film interference.

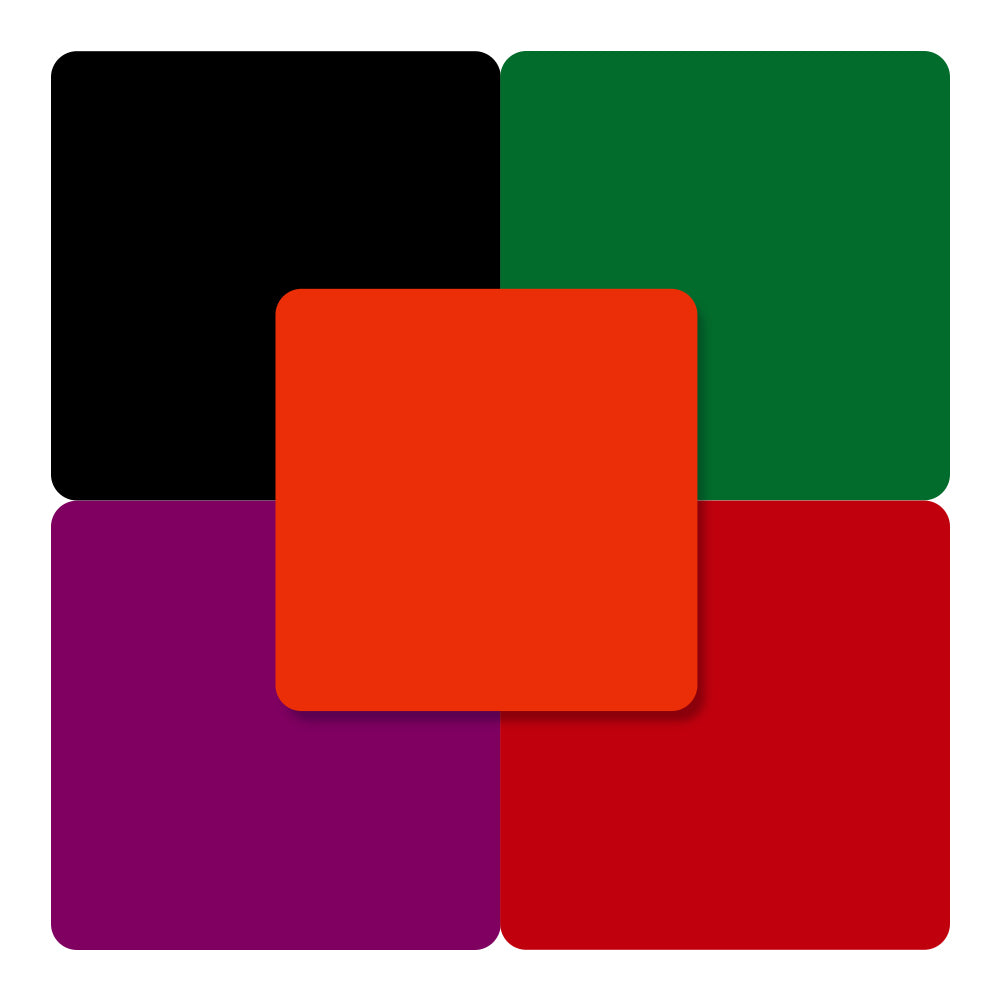

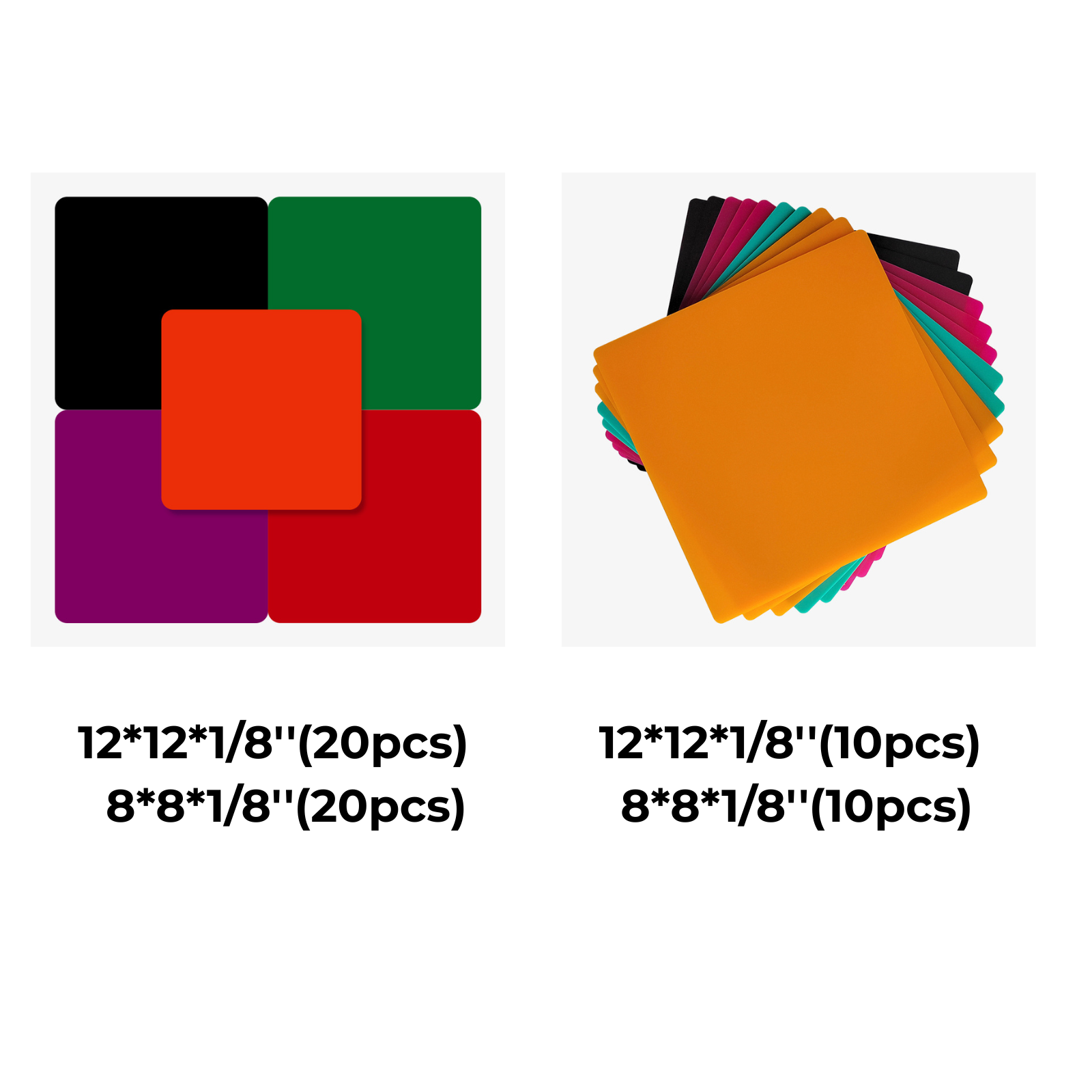

2. Color Depends on Oxide Layer Thickness

Different laser settings (power, speed, frequency, number of passes) change how thick the oxide layer becomes.

Thin layers reflect blue or gold.

Thicker layers produce purples, greens, or even reds.

Think of it like this: The laser is not adding pigment—it's adjusting how the surface interacts with light.

3. Video of Colour Lase Eteching

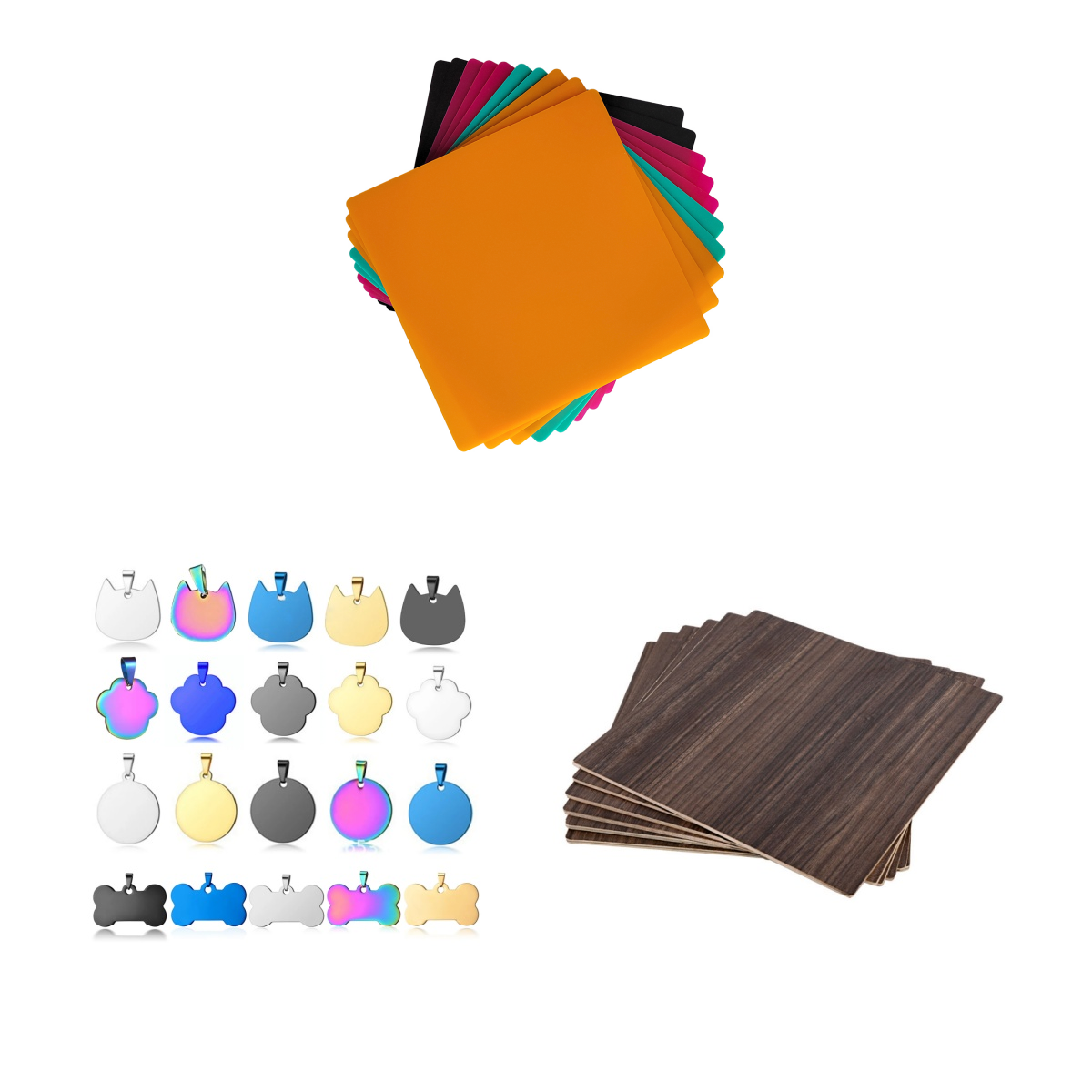

Part 2: Materials That Work Best for Color Laser Etching

Not all materials play nice with color laser etching—but a few shine brilliantly. From the rainbow effects on titanium to the deep blues on stainless steel, the secret lies in how each surface reacts to heat and light. Ready to see which ones make the magic happen?

1. Stainless Steel - Most Popular

- Why it works: Forms stable oxide layers at various thicknesses.

- Colors achievable: Blue, gold, purple, green, red.

- Laser type: Fiber or high-power diode (10W+), slow speed, low power.

- How common in everyday items: Very common – used in ~80% of households (tumblers, cutlery, tools, etc.).

2. Titanium - Vivid & Reliable Colors

- Why it works: Reacts readily with oxygen to create thick, colorful oxides.

- Colors achievable: Wide range—vibrant blue, pink, yellow, green.

- Bonus: Often used in medical devices, aerospace, and jewelry.

- How common in everyday items: Limited use – found in ~5–8% of consumer products (eyewear, watches, medical gear).

3. Niobium - Rare But Color-Rich

- Why it works: Similar oxide behavior to titanium.

- Colors achievable: Full rainbow range with very clear transitions.

- Use case: High-end art, jewelry, lab equipment.

- How common in everyday items: Very rare – <1% of daily-use items (mainly in artistic or custom jewelry).

4. Chromium-Rich Metals (e.g., Inconel, chrome-plated steel)

- Why it works: Can develop color under precise thermal conditions.

- Colors achievable: Limited but controllable (mainly gold, blue, bronze).

- Challenge: Requires careful calibration, narrow laser window.

- How common in everyday items: Moderate – ~5% of use cases (decorative trims, appliances, bike/car parts).

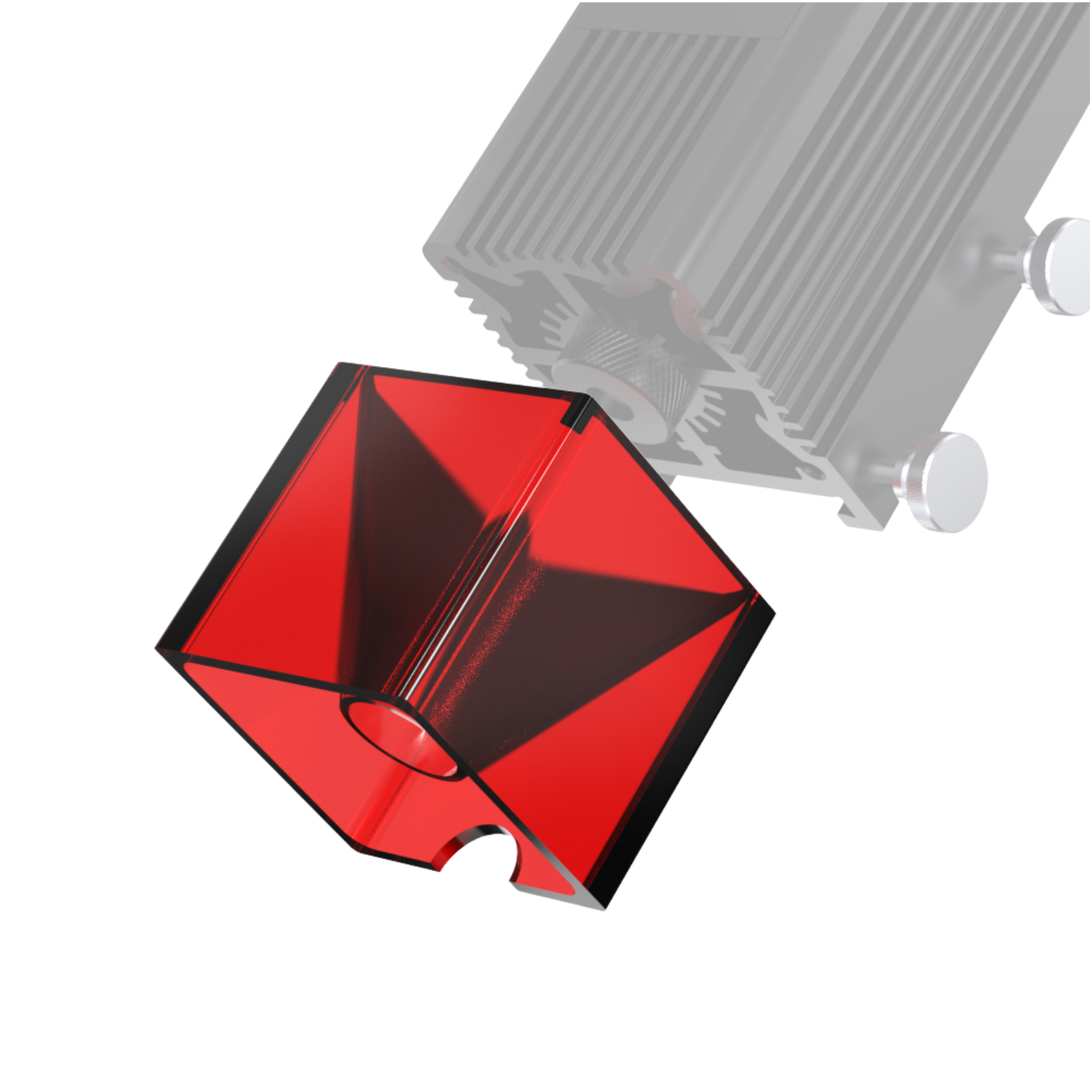

Part 3: Which Laser Types Are Ideal for Adding Color

Color laser engraving machines are built differently. You’ll need a laser that offers precision, control, and stable output to achieve vibrant hues through thermal oxidation.

Here are the top contenders:

1. Fiber Laser — Best for Consistent Color on Metals

Delivers ultra-focused, high-frequency beams that can precisely control surface oxidation.

- Color capability: Excellent on stainless steel, titanium, and niobium.

- Precision: Can fine-tune oxide thickness for vivid, stable color results.

- Bonus: Works well without additives or coatings.

2. High-Power Diode Laser (10W–20W+) — Best for Budget-Friendly Color Etching

Can generate enough heat for mild oxidation on stainless steel when speed and power are carefully controlled.

- Color capability: Limited but possible—blue, gold, bronze hues on polished stainless.

- Best use: Great for DIY users, personalized tumblers, or beginner setups.

3. CO₂ Laser — Not Suitable for Color Etching on Metal

CO₂ lasers are infrared-based and reflect off bare metal surfaces without effectively oxidizing them.

- Color capability: Nearly zero on metals unless pre-treated or coated.

- Note: Excellent for cutting/engraving organic materials (wood, leather), but not for color etching on metal.

Part 4: Best 5 Laser Machines for Colour Laser Etching

Choosing a reliable color laser engraving machine can make or break your results. Here are five top-rated options that deliver outstanding colour etching performance.

1. xTool F1 Ultra (20W Fiber + Diode)

Laser Type: Dual-laser (20W fiber + 20W diode)

Why xTool F1 Ultra Stands Out: Combines the precision of a fiber laser for metal color etching with the flexibility of a diode laser for wood, acrylic, and leather.

- Color Capability: Excellent full-spectrum color marking on stainless steel and titanium using adjustable frequency and pulse control.

- Best For: Hobbyists to professionals who want desktop power and portability.

- Price: Around $3,999

2. Mr. Carve M1 Fiber Laser (1064nm)

Laser Type: True 1064nm fiber laser

Why Mr. Carve M1 Fiber Laser Stands Out: Affordable fiber laser with solid performance on stainless steel; enables consistent contrast and mild color tones.

- Color Capability: Very good for grayscale and oxide-based color with no coating required.

- Best For: Beginners or makers focused on metal customization.

- Price: Around $2,000

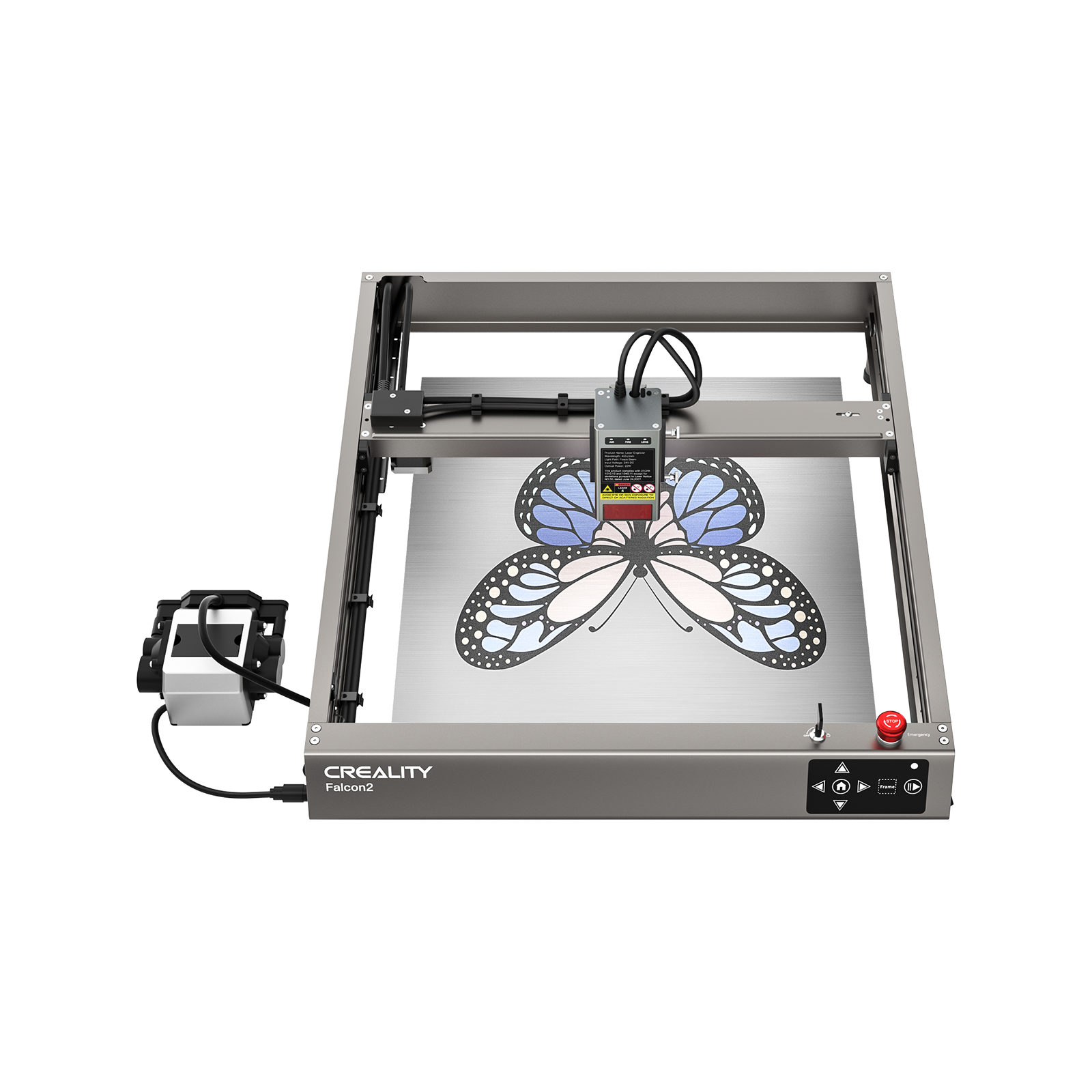

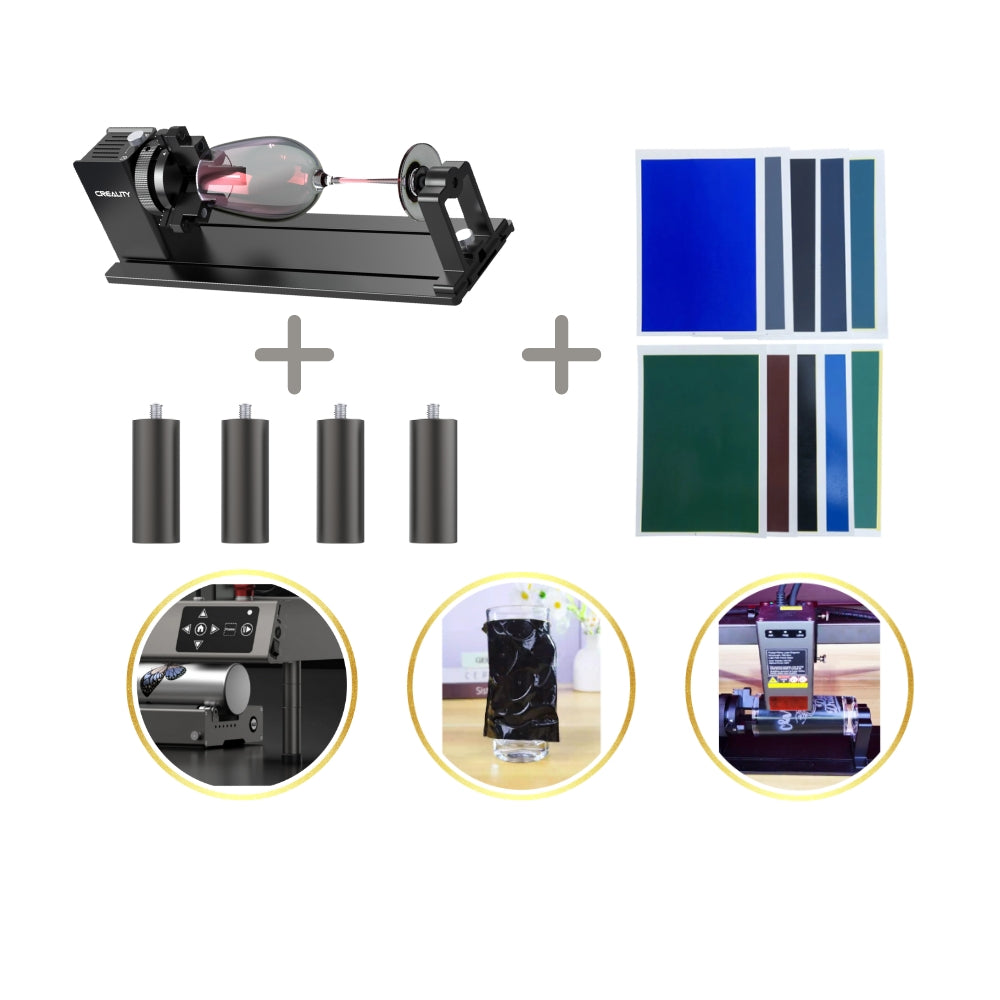

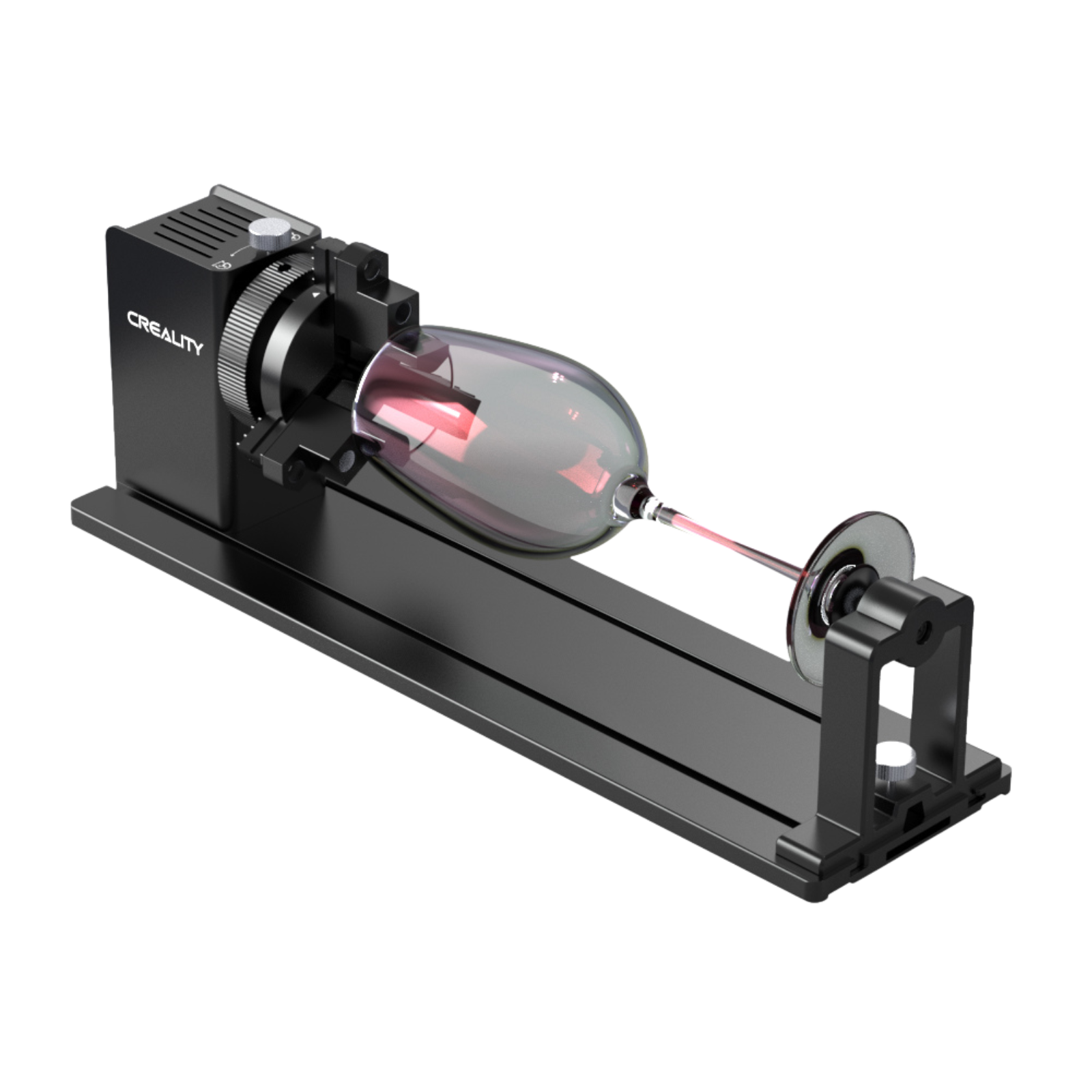

3. Falcon2 (22W or 40W Diode)

Laser Type: High-power diode laser (22W or 40W)

Why Falcon2 Stands Out: Versatile and beginner-friendly, with air assist and enclosure options.

- Color Capability: Can achieve basic oxide-based color on stainless steel, including blue, gold, and bronze tones.

- Best For: Makers seeking general-purpose cutting plus light color etching on metal.

- Price: $899–$1,499

4. Cloudray LiteMarker MP Series (60–100W MOPA Fiber)

Laser Type: MOPA fiber laser (adjustable frequency and pulse width)

Why Cloudray LiteMarker MP Series Stands Out: Industrial-grade color laser system with deep oxide colors and crisp gradients.

- Color Capability: Full rainbow spectrum on stainless steel, titanium, and coated metals.

- Best For: Production lines and high-end custom engraving.

- Price: Around $6,599+

5. LaserPecker LP5 (20W Fiber + Diode)

Laser Type: Dual-laser (20W fiber + diode)

Why LaserPecker LP5 Stands Out: Compact, app-controlled laser with high-speed galvo scanning and smart auto-focus.

- Color Capability: Reliable contrast and light color on stainless steel and anodized surfaces.

- Best For: Portable engraving and mobile businesses.

6. Quick Comparison Table

|

Machine |

Laser Type |

Color Etching Level |

Launch Date |

Best For |

Price (USD) |

|

xTool F1 Ultra |

Dual: 20W Fiber + Diode |

★★★★★ Full spectrum |

June 2024 |

High-end portability & variety |

~$3,999 |

|

Mr. Carve M1 |

1064nm Fiber |

★★★★ Mid–high range |

July 2023 |

Metal customization for beginners |

~$2,000 |

|

Creality Falcon2 |

22W / 40W Diode |

★★ Basic oxide effects |

Feb 2023 |

Hobbyists, general-purpose use |

~$899–$1,499 |

|

Cloudray MP Series |

60–100W MOPA Fiber |

★★★★★ Pro-level |

2024 |

Commercial & batch production |

~$6,599+ |

|

LaserPecker LP5 |

Dual: 20W Fiber + Diode |

★★★ Good contrast |

July 2023 |

Portable, app-powered projects |

~$2,999 |

Part 5: Is Color Laser Etching Right for You

Color laser etching is an exciting technique—but it's not for everyone. Whether it’s right for you depends on your goals, budget, and material needs. Here's a quick way to decide:

1. Color Laser Etching Might Be Right for You If

- You want to etch metals like stainless steel or titanium with permanent, vivid colors (no ink or paint).

- You're creating custom jewelry, gifts, branding plates, or premium signage.

- You prefer clean, chemical-free surface marking with artistic potential.

- You're using or willing to invest in a fiber or MOPA laser (or a high-precision diode for basic results).

- You need durability—the color won't fade, peel, or rub off.

2. It Might Not Be Ideal If

- You're mostly working with wood, acrylic, or plastic (color etching doesn’t apply—use traditional engraving).

- You need high-speed bulk production on a low budget.

- Your laser is CO₂ only, which can't etch bare metal for color.

- You expect bright, printed-like full-color images—color laser etching relies on light interference, not pigments.

Ready to Try It Yourself

Colour laser etching isn’t just tech—it’s magic. Imagine transforming bare metal into bold reds, glowing greens, and deep blues—all without a single drop of paint.

With the right laser and a bit of imagination, your ideas can come alive in vibrant color. Don’t stress about perfection—just start.